DSC operates by simultaneously heating (or cooling) a sample and a reference to prompt thermal transitions in the sample. These transitions, marked by changes in heat flow, are meticulously recorded against temperature. The resulting data, presented as a DSC curve, reveals critical thermal transition points, offering a window into the material’s thermal stability, composition, and purity.

To ensure the accuracy, repeatability, and reliability of DSC measurements, adherence to international standards is paramount. These standards, established by organizations such as the American Society for Testing and Materials (ASTM), the International Organization for Standardization (ISO), and the Japanese Industrial Standards (JIS), provide guidelines for DSC testing. They cover aspects like calibration, sample preparation, and interpretation of results, making DSC a universally accepted method for material characterization.

DSC’s versatility makes it invaluable in numerous fields. In the pharmaceutical industry, it aids in drug development by analyzing drug polymorphism and stability. Polymer scientists rely on DSC to evaluate material properties like crystallinity and thermal transitions. The food industry uses DSC to investigate lipid oxidation and protein denaturation, while environmental scientists assess the thermal decomposition of materials.

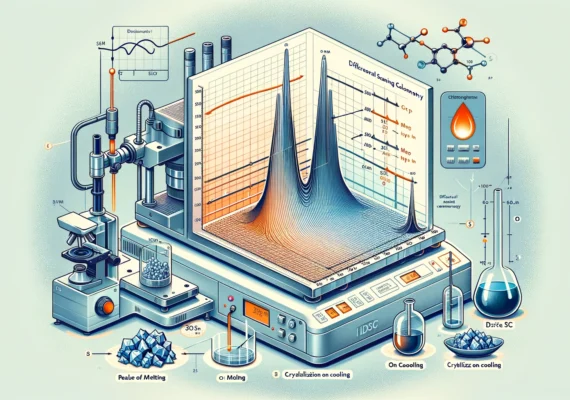

To complement this guide, let’s introduce an illustrative depiction of a DSC analysis. This visual will highlight the DSC curve with its significant phases—melting, crystallization, and the glass transition—alongside an image of a DSC instrument in action, underscoring the method’s practical application.