Step inside a plastic testing lab, and you'll find a bustling hub of activity where experts work tirelessly to evaluate the properties and characteristics of various plastic materials. From polymers to composites, every aspect of plastic undergoes meticulous examination to ensure it meets industry standards and regulatory requirements

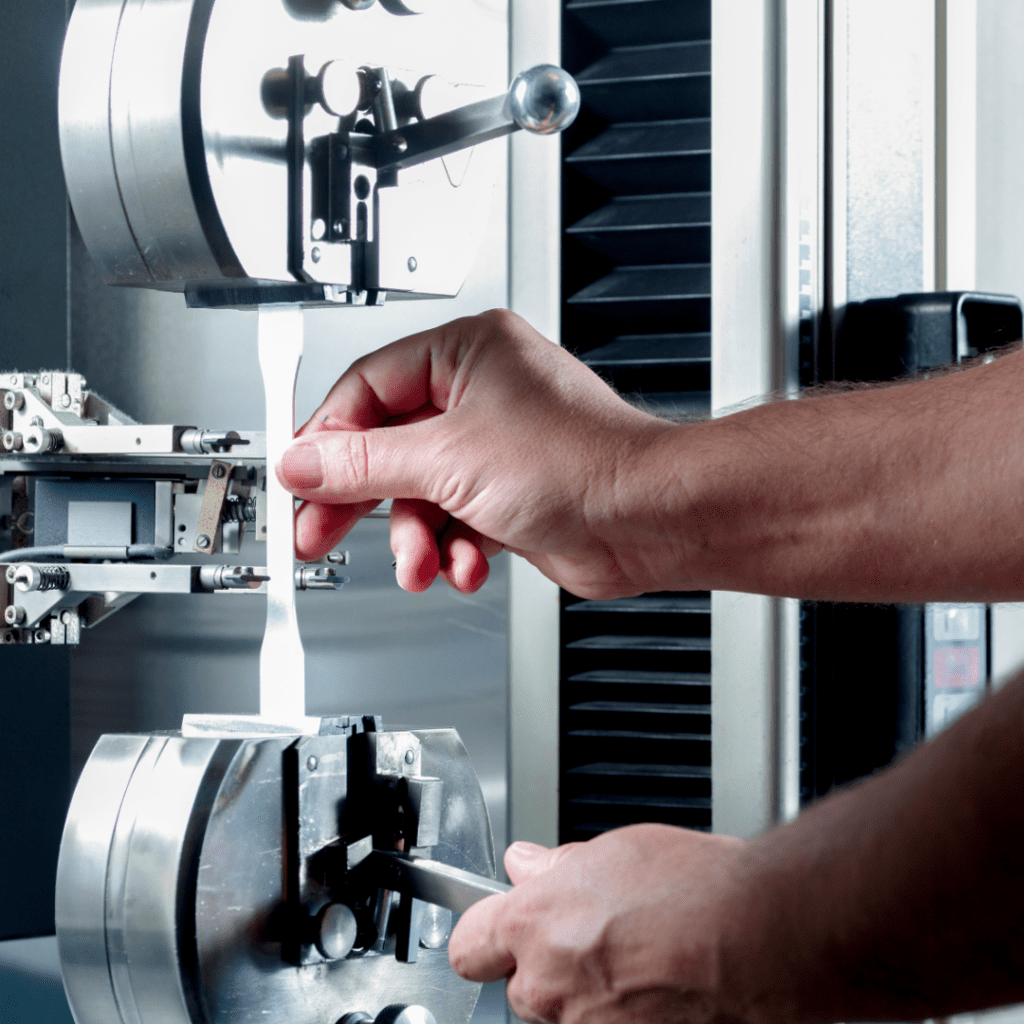

The testing procedures employed in a plastic testing lab are as diverse as the applications of plastic themselves. Mechanical testing assesses the material's strength, durability, and flexibility, providing crucial insights into its performance under different conditions. Chemical analysis delves into the composition of the plastic, detecting any harmful substances or impurities that may compromise its safety. Thermal analysis investigates how the material responds to temperature changes, helping engineers design products that can withstand extreme environments. Additionally, tests for electrical conductivity, flammability, and environmental impact further expand our understanding of plastic behavior

Beyond ensuring compliance with existing standards, plastic testing labs are also at the forefront of innovation and research. Scientists continuously explore new testing methods, develop advanced materials, and investigate sustainable alternatives to traditional plastics. By pushing the boundaries of knowledge and technology, these laboratories contribute to the ongoing evolution of the plastic industry, paving the way for safer, more efficient, and environmentally friendly solutions.

The insights gained from plastic testing labs have far-reaching implications across industries. Manufacturers rely on testing data to optimize their production processes, enhance product quality, and meet regulatory requirements. From automotive components to medical devices, the reliability of plastic materials plays a crucial role in ensuring the safety and performance of countless products. Additionally, ongoing research in areas such as biodegradable plastics and recycling technologies promises to address the environmental challenges associated with plastic waste.

General Questions For You

A plastic testing laboratory is a specialized facility equipped with advanced equipment and expertise to analyze the properties and characteristics of plastic materials. These labs conduct a comprehensive range of tests to evaluate factors such as mechanical strength, chemical composition, thermal behavior, and environmental resistance of plastics.

Plastic testing laboratories can seek accreditation from organizations such as A2LA (American Association for Laboratory Accreditation) or ISO/IEC 17025, which establish standards for testing quality and competence. Accreditation demonstrates that the laboratory operates according to internationally recognized guidelines and maintains high standards of accuracy and reliability in its testing procedures.

Yes, many plastic testing laboratories offer specialized testing services tailored to the specific needs of their clients. Whether it’s conducting unique analyses, developing custom testing methods, or addressing specific industry requirements, these labs work closely with their clients to deliver comprehensive testing solutions.