Materials testing encompasses a wide range of tests to evaluate the properties and performance of various materials. This includes tensile strength, impact resistance, thermal properties, and chemical resistance, among others.

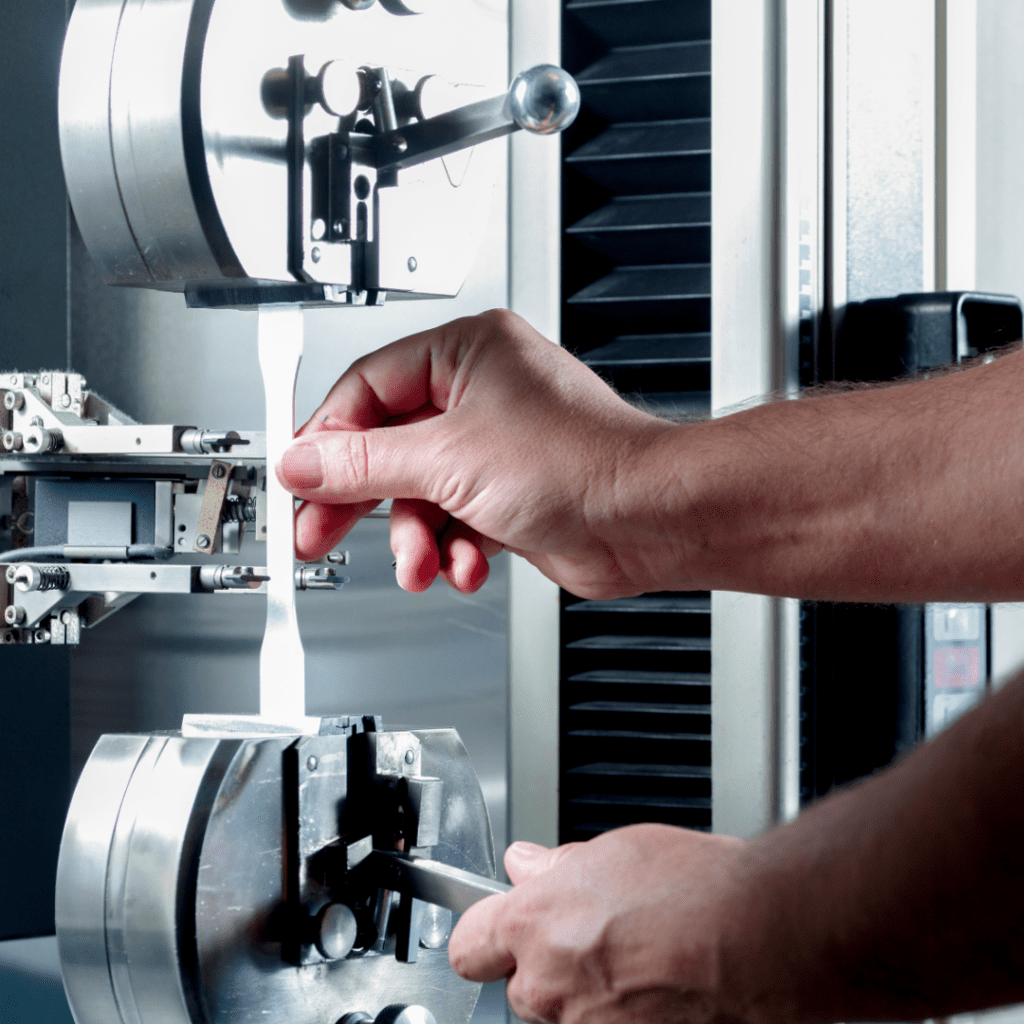

Plastic testing involves assessing the quality, composition, and performance of plastic materials. This includes tests for mechanical properties, such as hardness and flexibility, as well as chemical analysis to detect any harmful substances or contaminants.

Rubber testing evaluates the properties of rubber compounds, including elasticity, durability, and resistance to abrasion and tearing. These tests ensure that rubber products meet quality and safety standards for their intended applications.

NABL accredited labs adhere to rigorous quality standards prescribed by national and international accreditation bodies. This ensures that testing procedures are conducted with precision and accuracy, producing reliable and reproducible results.

Accurate testing is crucial for verifying the quality and performance of materials used in various industries. Whether it's ensuring the safety of consumer products or validating the structural integrity of industrial components, precise testing is essential for maintaining product quality and compliance with regulatory standards.

NABL accredited labs are equipped with state-of-the-art instrumentation and operated by highly skilled technicians and scientists. Their expertise ensures that tests are conducted accurately and efficiently, delivering reliable results.

NABL accredited labs adhere to strict confidentiality protocols to protect sensitive information and proprietary data. Clients can trust that their test results will be kept confidential and secure.

NABL accreditation is a formal recognition of the competence of a testing or calibration laboratory to perform specific tests or calibrations.

Accurate testing ensures that plastic products meet quality and safety standards, preventing potential hazards and ensuring customer satisfaction.

NABL accreditation involves rigorous assessment of a laboratory’s technical competence, quality management systems, and proficiency in conducting tests. This process helps ensure that test results are reliable and meet internationally accepted standards.

NABL accredited labs offer a wide range of testing services, including materials testing, plastic testing, rubber testing, and metals testing.