Horizontal Flammability Testing measures the burning rate of a material when exposed to a flame. The “HB” in UL 94 HB stands for “Horizontal Burn.” In this test, a material sample is placed horizontally, and a controlled flame is applied to one end. The goal is to determine how quickly the material burns under these conditions. The HB test is generally considered the most lenient of the UL 94 tests, as it involves slower burning rates and is often a minimum requirement for plastic materials.

The testing process follows a specific methodology to ensure consistency and accuracy. Here’s an outline of the typical steps:

Sample Preparation: Plastic specimens are cut to the required dimensions, typically 125 mm x 13 mm with a thickness of no more than 13 mm. The sample must be conditioned according to ASTM standards before testing.

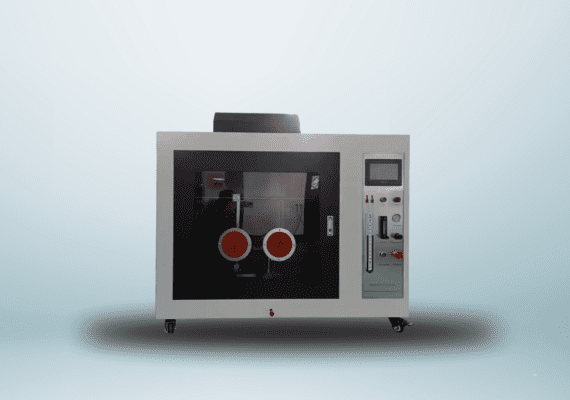

Application of Flame: The specimen is placed horizontally, and a small flame is applied to one end for a specified duration (usually 30 seconds).

Burn Rate Measurement: Once the flame is removed, the time it takes for the flame to travel across a marked portion of the sample is measured. The burning rate is then calculated in mm/min.

After the test, materials are classified based on their burning rates:

The HB classification is suitable for materials used in less fire-critical applications where minimal flame resistance is acceptable.

UL 94 HB testing is essential for various industries, particularly where plastics are used in products like electrical enclosures, automotive parts, or appliances. A material that meets UL 94 HB requirements helps manufacturers ensure that their products comply with safety standards, reducing the risk of fire-related accidents.

This test also aids designers and engineers in selecting appropriate materials for their applications, balancing performance with safety regulations.